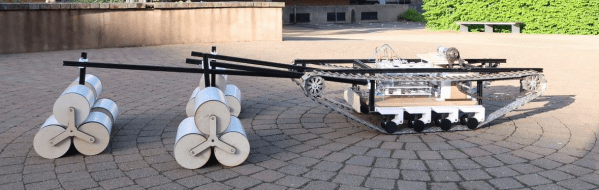

Dealing with all the wiring can quickly become a challenge on robots, especially the walking variety which have actuators everywhere. [Eric Yufeng Wu] sidestepped the wiring issue by creating Q8bot, a little quadruped where all the components, including the actuators, are mounted directly on the PCB.

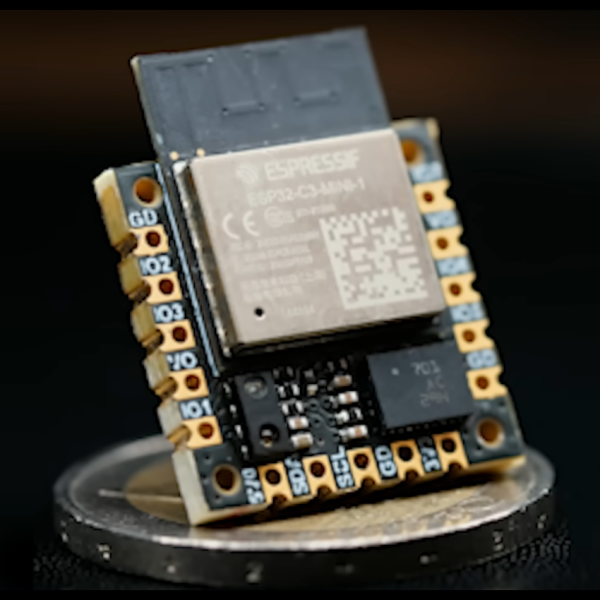

[Eric] uses a custom PCB as the spine of the robot, and the eight servos plug directly into connectors on the PCB. With their bottom covers removed, the servos screw neatly into a pair of 3D printed frames on either side of the PCB, which also have integrated 14500 battery holders. The PCB is minimalist, with just the XIAO ESP32C3 module, a boost converter circuit to drive the servos, and a battery fuel gauge. Each SCARA-style leg consists of four SLS 3D printed segments, with press-fit bearings in the joints.

The little one moves quickly, and can even do little jumps. For this prototype, most of the control processing is done on a laptop, which sends raw joint angles to the onboard ESP32 via the ESP-Now protocol. We think this little robot has a lot of development potential, and fortunately [Eric] has made all the hardware and software files available for others to build their own.

Continue reading “Little Quadruped Has PCB Spine And No Wiring”