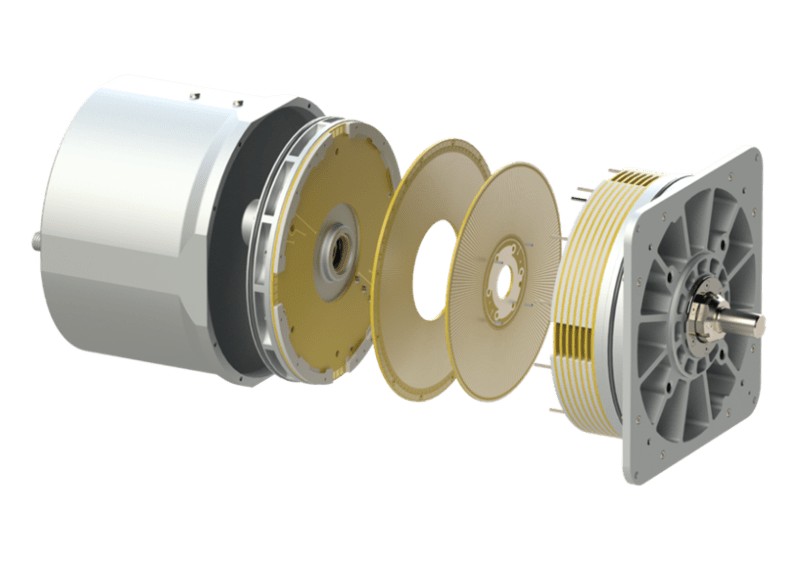

Electrostatic motors are now common in MEMS applications, but researchers at the University of Wisconsin and spinoff C-Motive Technologies have brought macroscale electrostatic motors back. [via MSN/WSJ]

While the first real application of an electric motor was Ben Franklin’s electrostatically-driven turkey rotisserie, electromagnetic type motors largely supplanted the technology due to the types of materials available to engineers of the time. Newer dielectric fluids and power electronics now allow electrostatic motors to be better at some applications than their electromagnetic peers.

The main advantage of electrostatic motors is their reduced critical materials use. In particular, electrostatic motors don’t require copper windings or any rare earth magnets which are getting more expensive as demand grows for electrically-powered machines. C-Motive is initially targeting direct drive industrial applications, and the “voltage driven nature of an electrostatic machine” means they require less cooling than an electromagnetic motor. They also don’t use much if any power when stalled.

Would you like a refresher on how to make static electricity or a deeper dive on how these motors work?

Near the bottom of the article:

At 1.5 T, a field achievable with iron, the theoretical magnetic shear limit is 1.79 MPa or 260 psi. At 3 kV/mm with atmospheric conditions, the theoretical electric shear limit is 79.65 Pa or 0.012 psi, a ~4 orders of magnitude deficiency for electrostatics compared with magnetics

And apparently nobody ever built a bigger motor then about 75Watt and an efficiency of 50% These are not going to replace big motors anytime soon. I’d be curious to see (niche?) applications where these motors are a good fit though.